JAL Engineering Co., Ltd. is an aircraft maintenance company that carries out maintenance of JAL Group aircraft and supports safe operation. In addition to JAL Group aircraft, the company also provides maintenance services for other airlines’ aircraft flying to Japanese airports.

The company is promoting various initiatives under the slogan “Zero Zero 100,” aiming for “zero irregular operations,” “zero inflight defects,” and a “100% on-time departure rate”. One of the main initiatives is the “Failure Prediction Project”. For many years, the company has been continuously improving the quality and efficiency of its maintenance operations to enhance the quality of its aircraft. One of the company’s most important efforts is “preventive maintenance,” which aims to identify and prevent defects before they occur.

In the past, preventive maintenance relied mainly on “five senses,” with mechanics checking the aircraft’s condition with their eyes and listening for unusual noises. In recent years, the company has been focusing on measures to analyze big data from the large amount of “flight data” acquired from sensors attached to aircraft, and to detect signs of failures. According to Toru Taniuchi, an analyst in the company’s Engineering Department, this initiative, called the “Failure Prediction Project,” began in 2016 and has so far produced several successful results.

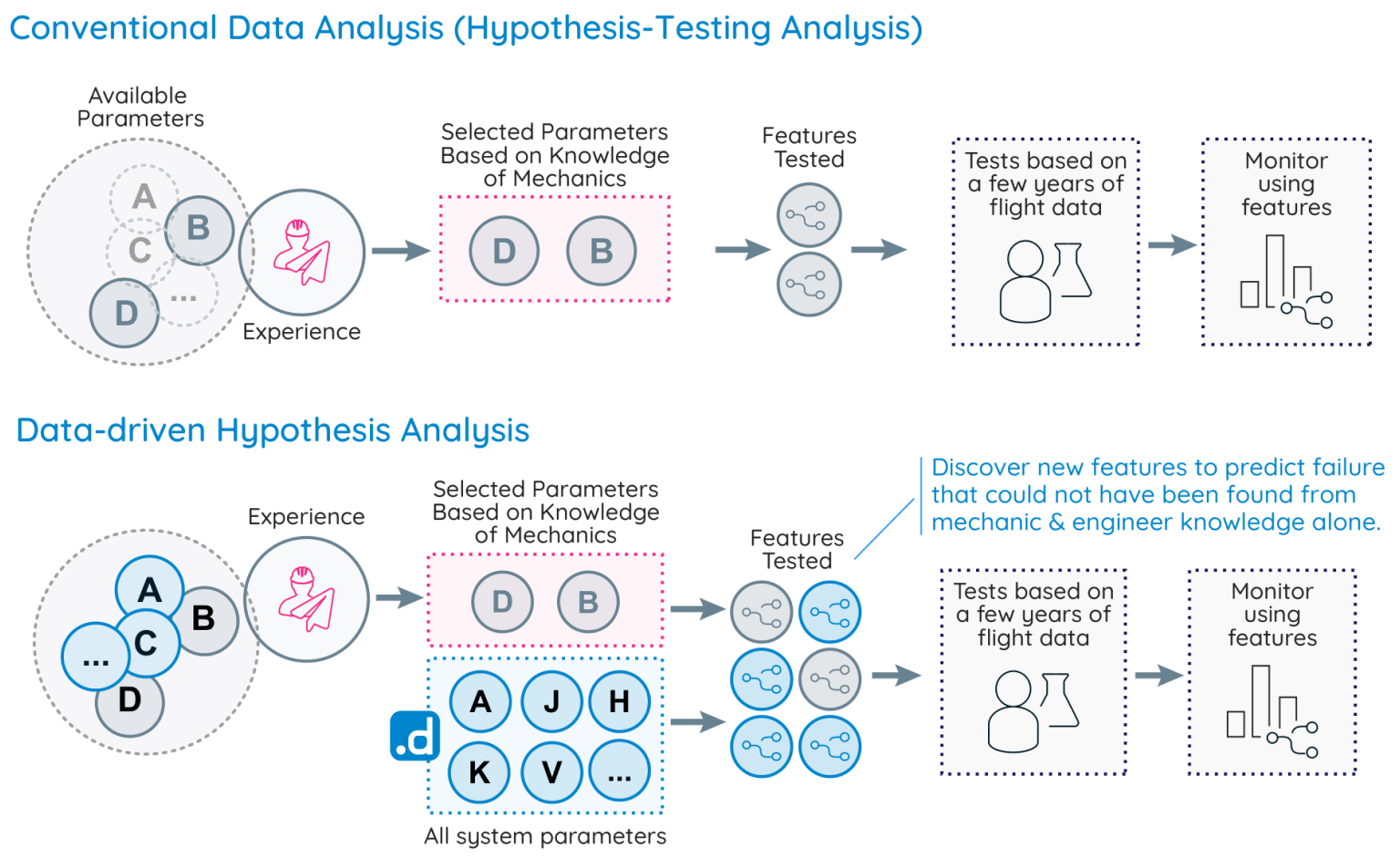

“We analyze historical sensor data acquired from each flight and historical maintenance data together. Our method is to first formulate a “hypothesis” of a scenario leading to a malfunction based on the experience and knowledge of mechanics and engineers, then verify the hypothesis with the data for the period where the actual failure occurred and find “ specific features” in the data that indicate signs of the failure. We then verify whether we can detect the predictive signs by using these specific features with more broad historical data. This series of methods is called within the company as “hypothesis-testing analysis.” To date, this method has steadily produced results, including the creation of about 100 prediction models that can detect signs of failures.” says Mr.Tanicuhi.