Discrete manufacturing and process industries have a gold mine of data. Industry 4.0 leaders use this data to uncover deep operational insights, streamline processes, and enable faster, more accurate decision-making with AI. dotData helps manufacturers leverage data from multiple sources to discover key business signals, build effective AI/ML models for predictive maintenance, identify quality issues, and optimize supply chains.

dotData Transforms

Manufacturing with AI

Leverage intelligent automation powered by AI to increase yield, reduce operating costs, and improve factory agility.

Ai-Powered Analytics to Enable Smart Manufacturing

How AI Changes Manufacturing

Manufacturing applications such as anomaly detection and real-time quality monitoring are latency-sensitive and require ultra-fast responses. Real-time data processing allows manufacturers to take action immediately to prevent undesirable consequences and requires streaming analytics capability. dotData Stream, a containerized AI engine for real-time prediction capabilities, lets you deploy predictive models on edge devices such as machines, local gateways, or servers in your factory and accelerates Industry 4.0 adoption.

Optimizing Design and Prototyping for Enhanced Product Performance

By extracting signals from the relationship between raw materials, processes, and product performance, manufacturers can increase product quality and streamline production. This approach is also applied in materials informatics, where dotData helps predict physical properties from sample data, aiding the discovery of new compounds. In the consumer goods sector, manufacturers leverage data on consumer behavior and preferences to accelerate product development, reducing time and costs.

Supply Chain Management (SCM)

dotData transforms supply chain management (SCM) by optimizing demand, pricing, and inventory forecasts. dotData has helped manufacturers reduce inventory by discovering signals from sales history and market trends to improve accuracy in forecasting. A chemical manufacturer enhanced its procurement process by analyzing raw material demand and prices, while a metal manufacturer optimized production volumes and inventory by forecasting steel product demand. dotData’s AI-driven approach automates and accelerates the creation of multiple time series forecast models, allowing manufacturers to quickly adapt to changing market conditions, reduce overstock or stockouts, and lower shipping costs through supply chain optimization.

Optimizing Plant Operations for Better Quality and Efficiency

A manufacturer used dotData to analyze the relationship between plant operating conditions and product quality, identifying the optimal conditions for producing high-quality products with lower power consumption. This led to improvements in both production efficiency and cost-effectiveness. Additionally, in factory automation, dotData’s AI automates the control of manufacturing actuators, further enhancing process efficiency. This automation helps maintain consistent product quality while reducing costs and increasing overall operational efficiency.

Transforming Customer Experience in Product Development, Sales, and Aftermarket Services

dotData’s AI helps improve customer experience from product development to aftermarket services. B2B2C businesses, like automobile and consumer goods manufacturers, use insights from consumer data and collaboration with wholesalers to understand customer needs better and create more personalized products. Additionally, manufacturers analyze product defects and customer feedback to enhance product quality and service, boosting customer satisfaction and brand loyalty.

What Our Customers Say

Exeter Finance

The biggest problem is that, when doing it manually, it’s just a repetitive, trial-and-error process that takes time. dotData solves a problem I’ve been trying to solve for 20 years.

sticky.io

I was spending 95% of my time wrangling data…now I can offload most of that work and just focus on delivering viable patterns and insights.

Use Cases

A Global Automobile Manufacturer

A Multinational Industrial Supplier

News

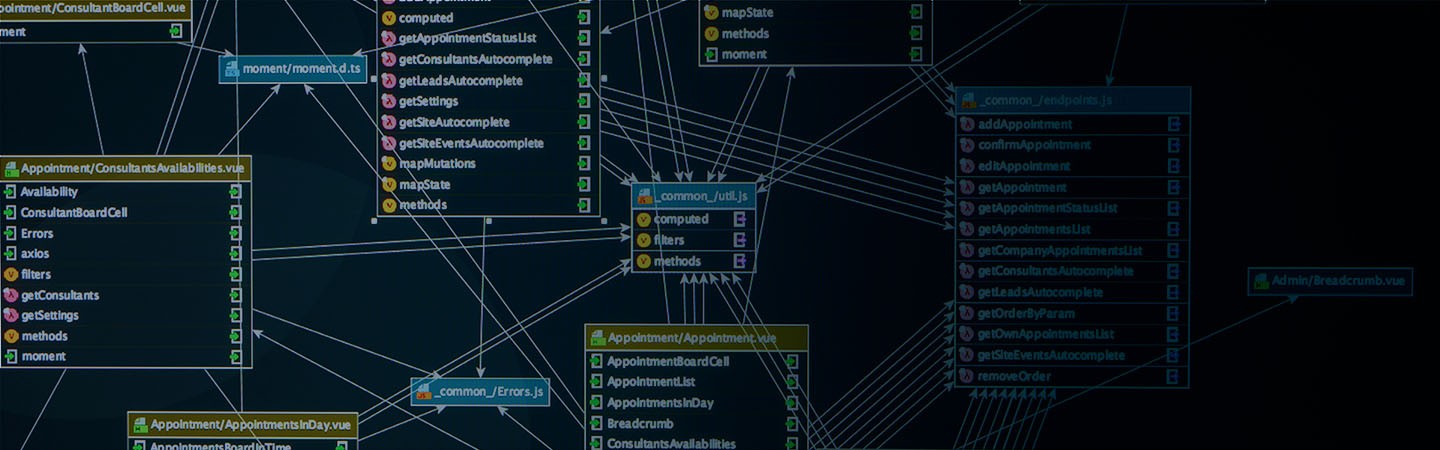

dotData's AI Platform Maximize Data Utilization through Feature Discovery

dotData leverages automated feature engineering to build models using machine learning, enhancing data by accumulating feature values as assets and extracting valuable insights, enabling businesses to become more data-driven. Our platform satisfies a wide range of needs, including business transformation, and support the effective use of data and AI to drive innovation and growth.

Request a Demo

We offer support tailored to your needs, whether you want to see a demo or learn more about use cases.