Yokohama rubber has been working to explore the relationship between input and output data in the design process for some time. However, Dr. Koishi says that there were limitations to the number of factors that could be handled and that the number of factors themselves could not be analyzed in detail.

”We have been working to explore the relationship between input and output data for some time, but there were various issues, such as the limited number of factors that could be handled and the fact that the factors themselves had to be set by people familiar with both the subject of analysis and data analysis,” says Dr. Koishi.

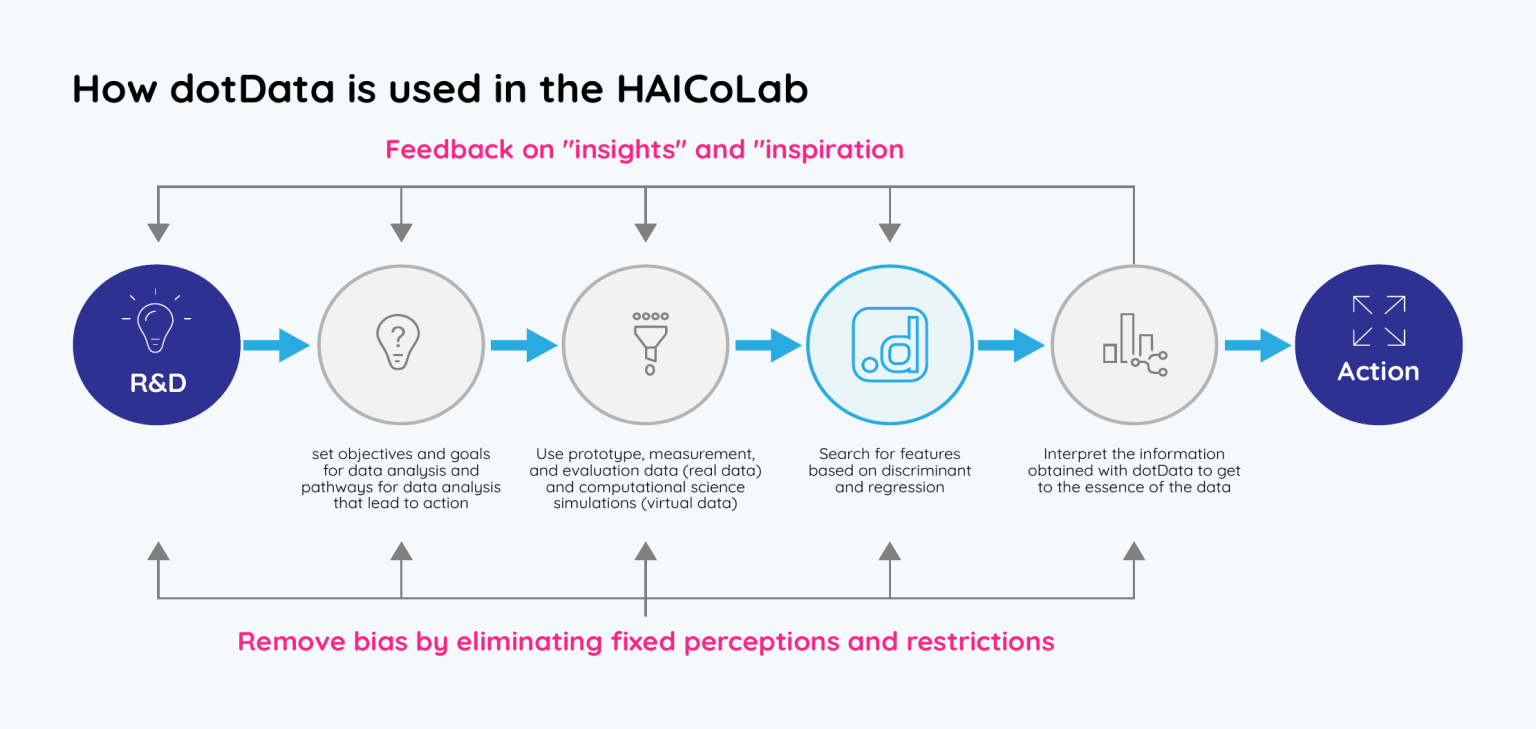

Their interest in dotData was largely due to its great advantage of automatically finding and extracting important features by entering outputs (objective variables to be predicted) and inputs (various explanatory variables related to design and processes). dotData’s ability to automatically extracts features in a form that is understandable to humans is a key point for “human-AI collaboration”. This was exactly in line with the company’s AI utilization policy of “collaboration between humans and AI.

After conducting a proof of concept using dotData on a trial basis, the effectiveness of the system was confirmed, and the decision was made to formally introduce it into the process. The first application of dotData was in the design of high-performance tires. High-performance tires mounted on sports cars require exceptional driving performance and stability. “We were working on a project to review the conditions of the manufacturing process, which involves mixing rubber materials, molding the tire, and vulcanizing it, along with the design specifications for high-performance tires,” says Dr. Koishi.

The data obtained from each process in the prototype evaluation was compiled and fed into dotData, which automatically designed “feature values” that were thought to contribute to the improvement of the prototype’s characteristics. The project members repeated the process of automatically designing and interpreting the “feature values” and incorporating them into the next prototype, and “performance and stability improved step by step. Although development work continues, there are many findings that were only realized after being confronted with data patterns discovered in the process of utilizing dotData,

“We call such discoveries secondary effects, and we consider them to be the results of utilizing dotData,” says Dr. Koishi.

The data obtained from all manufacturing processes from design, mixing, extrusion, rolling, molding, vulcanization, and inspection, and the relationship between them and tire measurement and evaluation data are analyzed by dotData to further improve product performance, stabilize quality, and increase productivity. The company is promoting a “manufacturing revolution” to further improve product performance, stabilize quality, and increase productivity by analyzing the relationship between these data and tire measurement/evaluation data.